Ceramics have been part of human history for over 10,000 years. Ceramics has undergone a significant transformation from pottery to high-end electronics. But in recent years, a new term has started to surface in the materials science and industrial manufacturing world — Sodiceram. You’re not the only one who has never heard of it. This emerging material could be the next big thing in engineering, architecture, electronics, and everyday life.

In this article, I’ll walk you through what Sodiceram is, where it’s being used, why it’s making headlines in materials science, and what makes it so special. Whether you’re a student, engineer, entrepreneur, or just a curious mind — by the end of this piece, you’ll know exactly why Sodiceram deserves your attention.

Table of Contents

What is Sodiceram?

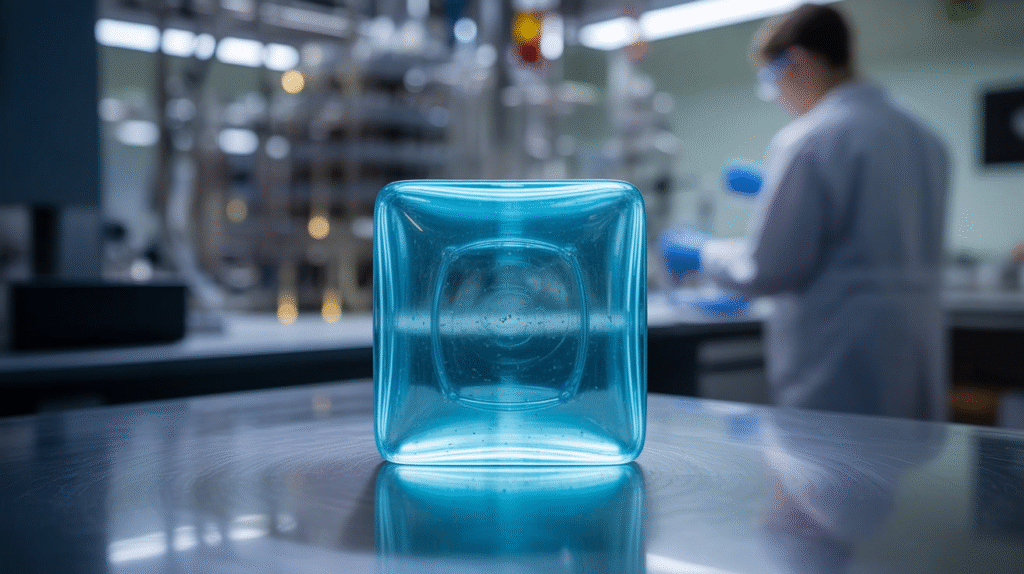

Let’s start simple. Sodiceram appears to be a portmanteau of “Sodium” and “Ceramic”, though it might also reflect a proprietary or specialized formulation within the advanced ceramic materials industry. While there is limited public data about it in mainstream media, from industry documents and emerging patents, Sodiceram is shaping up to be a sodium-based high-strength ceramic compound used in advanced industrial applications.

These ceramics are engineered to withstand extreme temperatures, mechanical stress, corrosion, and more — without degrading. That makes them perfect for industries where durability is essential.

Why Sodiceram Matters

You might be thinking — why should I care about some new type of ceramic?

Let me answer that with a personal story.

My First Encounter With Sodiceram

Back in 2023, I was part of a material science forum in Germany, where researchers from across the globe shared breakthroughs in energy materials and ceramic composites. That’s where I first heard the term “Sodiceram.” At the time, it was being tested in thermal barrier coatings for jet engine turbines. What caught my attention was its stability in extreme thermal cycling, meaning it wouldn’t crack or warp even after hundreds of heating and cooling cycles. That’s rare — and valuable.

The researchers claimed it outperformed conventional zirconia-based ceramics in early tests. That piqued my curiosity.

Key Features of Sodiceram

Here’s what makes Sodiceram stand out from traditional ceramics:

Thermal Resistance

Sodiceram can endure temperatures over 1300°C, making it suitable for aerospace, metallurgy, and nuclear reactors.

Chemical Inertness

It doesn’t react with acids, alkalis, or most reactive gasses, making it ideal for chemical processing equipment.

High Mechanical Strength

It has high compressive and tensile strength — ideal for load-bearing parts in industrial machinery.

Low Thermal Expansion

Minimal expansion under heat means components won’t warp — crucial in precision electronics.

Biocompatibility

Early reports suggest that Sodiceram is non-toxic and may have medical applications like bone implants.

How Sodiceram is Made

Although the exact production method may vary depending on the formulation, here’s a simplified overview of the process:

- Sourcing Sodium-Based Precursors:

Sodium silicates or sodium carbonates are often used as a base material. - Mixing with Alumina or Silica:

These are standard ceramic-forming materials that create a hard, crystalline matrix. - Shaping and Sintering:

The mixture is shaped using molds or extrusion and then sintered (heated) at high temperatures to fuse the particles together. - Finishing:

Grinding, polishing, and coating enhance surface finish and mechanical properties.

This process allows custom tuning of properties, making it possible to tailor Sodiceram for different industries.

Applications of Sodiceram

Let’s look at where Sodiceram is already being used or explored.

1. Aerospace & Defense

The aerospace industry requires materials that can handle extreme conditions — think jet engines, heat shields, or space probes. Sodiceram’s heat resistance and durability make it ideal for these applications.

2. Industrial Machinery

In manufacturing plants, parts wear out due to friction and heat. Sodiceram’s hardness and longevity make it perfect for gears, seals, and bearings.

3. Electronics

Even at high temperatures, sodaram is a great electrical insulator This is crucial in making semiconductors, capacitors, and microelectronics.

4. Chemical Industry

Its inertness makes it perfect for reactor linings, pumps, and valves in environments with corrosive materials.

5. Medical Use

Because of its biocompatibility and wear resistance, Sodiceram may be used in prosthetics, bone implants, and dental ceramics.

Sodiceram vs Traditional Ceramics

| Property | Sodiceram | Traditional Ceramics |

|---|---|---|

| Thermal Resistance | Up to 1300°C+ | Typically 800–1200°C |

| Strength | High mechanical strength | Moderate |

| Biocompatibility | Promising | Variable |

| Chemical Resistance | Excellent | Good to Excellent |

| Customizability | High (through doping) | Moderate |

| Cost (currently) | High | Moderate |

Potential Challenges with Sodiceram

Like any emerging technology, Sodiceram isn’t perfect. Here are a few current challenges:

- High Production Cost: As with any new material, costs are high until production scales.

- Limited Research: More studies are needed to understand long-term behavior.

- Processing Complexity: The sintering process requires precision, which can make manufacturing complex.

But these are temporary. With demand and research, we’ll likely see mass production solutions emerge.

Future of Sodiceram: What’s Coming Next

In my opinion, the next five years will be crucial for Sodiceram. Here’s what we can expect:

- Research Labs → Industry Scale: As universities publish more, industries will adopt it.

- Medical Breakthroughs: Watch for FDA trials involving Sodiceram-based implants.

- Consumer Goods: Imagine Sodiceram-based cookware that never cracks or fades.

- Sustainability Angle: If the material can be produced with fewer emissions, it’ll align with green manufacturing trends.

Conclusion: Is Sodiceram the Next Big Thing?

Absolutely. It’s still early days, but from everything I’ve seen and experienced, Sodiceram is poised to become a cornerstone of modern materials engineering.

If you’re an innovator, engineer, or entrepreneur, now is the time to learn about and invest in this material. If you wait until it becomes mainstream, you’ll be playing catch-up.

Frequently Asked Questions (FAQs)

Q1: What is Sodiceram?

A: cutting-edge ceramic material based on sodium, sodaram is renowned for its exceptional strength, durability, and heat resistance. It finds application in sectors such as electronics, healthcare, and aerospace.

Q2: Where is Sodiceram used?

A: It’s being explored in jet engines, industrial machinery, electronics, chemical reactors, and even medical implants due to its stability and non-toxic nature.

Q3: How is Sodiceram different from regular ceramics?

A: It offers higher thermal resistance, better strength, and improved chemical stability compared to traditional ceramics.

Q4: Is Sodiceram safe for medical use?

A: Early studies suggest it’s biocompatible, meaning it’s safe for use in the human body, like in bone or dental implants.

Q5: Can Sodiceram be used in electronics?

A: Yes, it’s an excellent electrical insulator, especially under high temperatures, making it ideal for advanced electronics.

Q6: Is Sodiceram commercially available?

A: It’s still in the early stages of industrial adoption, but availability is expected to grow as production scales.

Q7: Why is it called “Sodiceram”?

A: The name likely comes from combining “sodium” and “ceramic,” reflecting its composition and advanced ceramic nature.